Background and Motivation

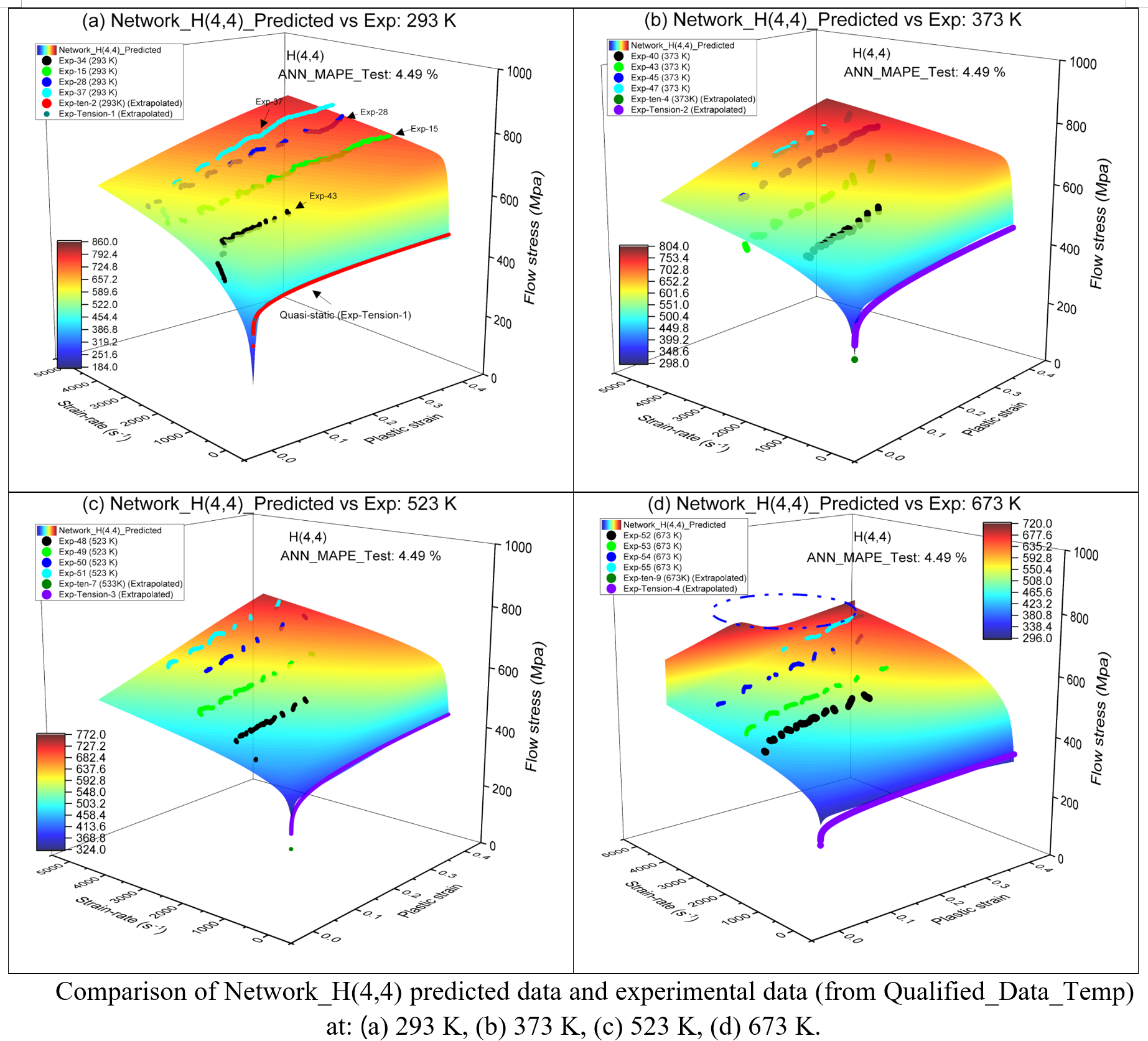

Dynamic flow stress of materials is governed not only by strain and strain-rate, but also by temperature, especially under high strain-rate loading where adiabatic heating and thermal softening become significant. Accurately capturing the coupled effects of these three variables remains a major challenge in constitutive modelling.

Conventional approaches often rely on sequential fitting procedures and simplified assumptions, leading to large uncertainties and poor predictive capability, particularly at elevated temperatures. Moreover, discrete experimental data obtained from SHPB tests are difficult to exploit effectively in a three-dimensional variable space.

Motivated by these limitations, this work extends the data-driven framework developed in Part 1 to a three-variable space of strain, strain-rate, and temperature. By integrating qualified experimental data, artificial neural networks, and tensor decomposition techniques, the study aims to obtain accurate and physically consistent dynamic flow stress equations suitable for high-rate and high-temperature applications.

Highlights

•

Extend the methodology to determine dynamic flow stress by SHPB in (strain, strain-rate) space (Part 1) to (strain, strain-rate, temperature) space.

•

CANDECOM/PARAFAC (CP) decomposition method is used together with ANN to describe dynamic flow stress.

•

The method has higher accuracy and effectiveness.

Xianglin Huang, Q.M. Li, Determination of dynamic flow stress equation based on discrete experimental data: Part 2 dynamic flow stress depending on strain, strain-rate and temperature, International Journal of Impact Engineering, Volume 206, 2025, 105432, ISSN 0734-743X, https://doi.org/10.1016/j.ijimpeng.2025.105432.